LV- Lamination Vinyl

LV- Lamination Vinyl

Make Your Designs Shimmer and Sparkle!

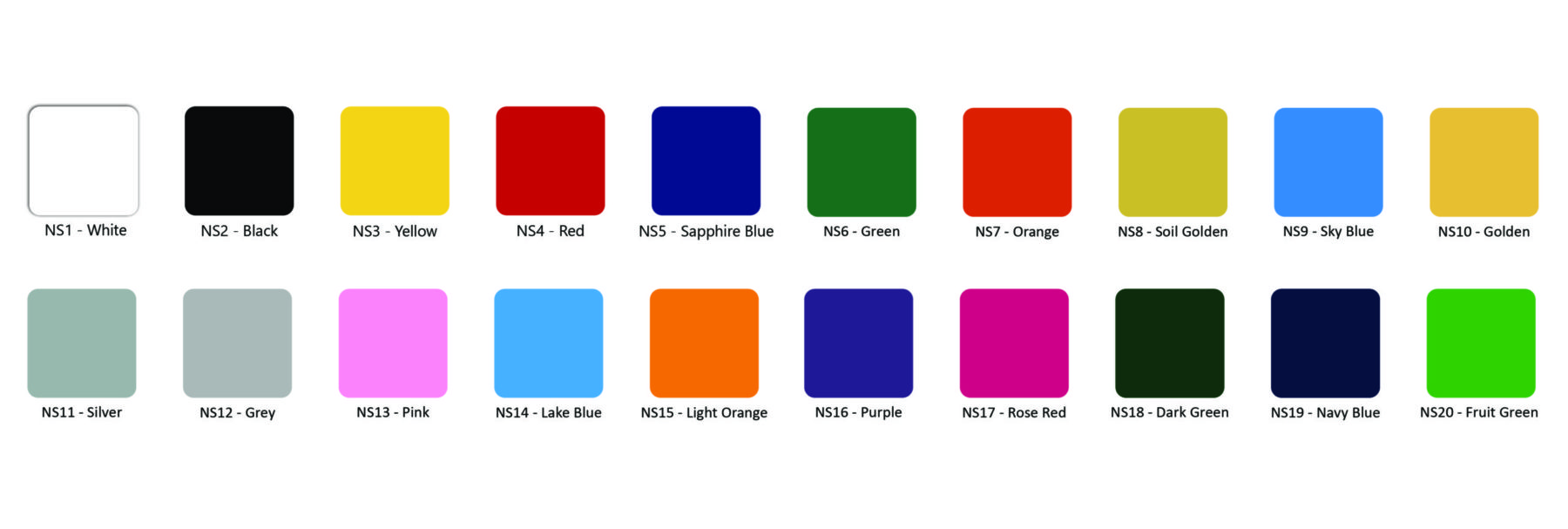

LV- Lamination Vinyl. Sparkle™ Heat Transfer Vinyl is a fashionable alternative to Glitter HTV by Siser®. Specially constructed to be soft to the touch, each color includes silver glitter specks embedded in the material so designs have a smooth finish. Sparkle is available in 14 colors, including silver and gold. Looking to layer? Sparkle can be layered for ultimate bling! Think outside the box and use Sparkle HTV on shoes, belts, and other hard-to-print items. If you like to keep it simple, Sparkle can be applied to t-shirts, hoodies, sweats and scrubs too!

What is LV Lamination Vinyl?

Lamination Vinyl is a type of plastic material that is used to protect and enhance documents or graphics. It is made from a combination of PVC (polyvinyl chloride) and PET (polyethylene terephthalate), which gives it a unique combination of strength and flexibility. Lamination Vinyl is available in different finishes, including gloss, matte, and textured, allowing for a variety of applications.

Benefits of Lamination Vinyl

Lamination Vinyl offers several benefits over other types of lamination materials, including:

Durability

Lamination Vinyl is highly durable and resistant to scratches, tears, and punctures. This makes it an ideal material for protecting important documents, such as certificates, diplomas, and identification cards.

UV Protection

LV Lamination Vinyl provides excellent UV protection, preventing documents or graphics from fading or yellowing over time. This makes it an ideal material for outdoor applications, such as vehicle graphics and outdoor signs.

Water and Chemical Resistance

Lamination Vinyl is water and chemical-resistant, which makes it ideal for applications that require protection from moisture and chemicals, such as labels and decals.

Versatility

People use Lamination Vinyl as a versatile material for a wide range of applications. You can use it to enhance the appearance of documents, create custom graphics, or protect surfaces from scratches and wear.

Applications of LV Lamination Vinyl

People use Lamination Vinyl in a wide range of applications, including:

Paper Document Protection

People commonly use LV Lamination Vinyl to protect paper documents like certificates, diplomas, and awards. This helps to preserve the documents and prevents them from becoming damaged over time.

Custom Graphics

You can use Lamination Vinyl to create custom graphics for a variety of applications, including vehicle graphics, signs, and banners. It is available in different finishes, allowing for a variety of creative options.

Labels and Decals

Manufacturers use LV Lamination Vinyl to protect labels and decals from moisture and chemicals while printing custom designs, logos, and text, making it an ideal material for branding and marketing.

Surface Protection

People use LV Lamination Vinyl to protect surfaces such as tables, countertops, and floors from scratches and wear by applying a durable and protective layer.

How to Choose the Right LV Lamination Vinyl

When choosing LV Lamination Vinyl, there are several factors to consider, including:

Thickness

Lamination Vinyl is available in different thicknesses, ranging from 1.5 mil to 10 mil. Thicker vinyl provides more durability and protection but may be less flexible and harder to work with.

Finish

Lamination Vinyl is available in different finishes, including gloss, matte, and textured. The finish you choose

Sparkle applies To

100% Cottoned

100% Polyester

Poly/Cotton Blends

Leather

Sparkle™ Snowstorm

Settings for Craft and Professional Cutters

How to apply VENYL® HTV

Printable version of all HTV application instructions

Home Iron Instructions

- Home Iron Instructions

- Set iron dial between Cotton and Linen

- Cover with Heat Transfer Cover Sheet or Multipurpose Paper

- Place on flat, hard surface (ironing board not recommended)

- Press iron with medium/firm pressure (do not slide iron)

Heat Press Instructions

- Cover with Heat Transfer Cover Sheet or Multipurpose Paper

- Preheat garment for 2-3 seconds

- Apply design at 305°F/150°C (EasyPress® users add approx. 30°)

- Use medium pressure for 10-15 seconds

- Peel carrier hot or cold

Recommended Accessories:

Multipurpose Paper or Heat Transfer Cover Sheet Wait 24 hours before first wash. Machine wash warm or cold with mild detergent. Dry on normal dryer setting. Do not dry clean.

Liquid fabric softener not recommended.